Metafram ® Self Lubricating Bearings

Metafram sintered bearings and bushings are inherently self-lubricating. They allow use over a wide range of speed and load while having a long service life.

The self-lubricating function helps reduce maintenance costs and increase product life. The uses are multiple: industrial machines, automobile, electric motor, agricultural machinery, aeronautics, etc...

- Maintenance free product due to self-lubricating

- Sintered self-lubricating bushings are 50% cheaper compared to ball bearings

- Possibility of complex shapes with sintered technology

- High precision parts

- Excellent surface condition

- Reduced weight compared to non-sintered components

- Possibility of machining

- Permanent lubricant film with self-lubricating

- Low coefficient of friction

- Reduced noise

- Low speed performance and shock resistant

- Good corrosion resistance

With a wide range of alloys (iron, copper, etc..) and a high level of customization, sintered self-lubricating METAFRAM bearings and bushings adapt to your uses.

Our R&D team provides you with solutions adapted and personalized to your bushing and bearings needs.

Our Metafram range

Ranging from 2 mm to 125 mm in diameter for our bushings and bearings, we have the possibility of supplying you large as well as small volumes.

Bronze BP25

Good coefficient of friction

Good corrosion resistance

Recommended for high speeds

Shaft surface finish Ra <0.6

Shaft hardness > 80kg / mm2

Iron alloy FP20

Recommended for medium or low speeds

Good bearings strength

Recommended for high payloads

Shaft surface finish Ra < 0.3

Shaft hardness > 120 kg/mm2

Iron alloy SO16

Recommended for medium or low speeds

Good bearing strength

Recommanded for very high payloads

Shaft surface finish Ra <0.3

Shaft hardness > 120 kg / mm2

Metafram parts with no Standard Sizes and Specific Lubricants

- If you need small quantities, our partners can provide machined parts from our blanks in accordance with METAFRAM guidelines and your drawings

- For large quantities or repetitive series, we can design customized tooling

- To optimize your equipment, we can design sintered bearings and bushings with specific shapes to fit your special applications

High payload, low speed

(rolling mill, press, lifting gear, heavy-duty vehicles). Standard blanks with SO 16 and TR 16 material grades (see the material grades brochure).

High or low temperature,

In situations where the operating temperature lies outside the -5/+90˚C range, we can change the impregnation lubricant used.

Immersion, corrosive fluid splashing

we have a solution based on sold lubricant

Impregnation with oil suitable for contact with foodstuffs (FDA standard)

How does Metafram self-lubricating bearings and bushings work?

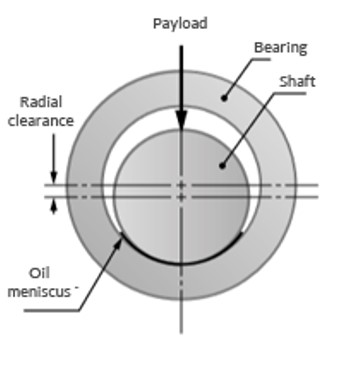

Stationary position:

Presence of an oil meniscus at the point of contact through the action of capillary forces

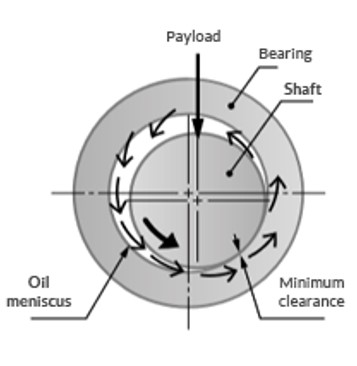

Rotating shaft:

The oil is driven by the rotation of the shaft and forms an oil wedge that produces the pressure necessary to lift the shaft.

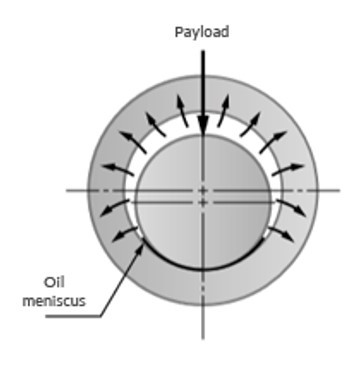

After operation

The oil is reabsorbed by the porous bearing, under the action of capillarity.

Metagliss product

Self lubricating friction plates

Our team remains at your entire disposal to develop customized self-lubricating friction plates which meet your requirements.