The Metafram bronze BP25 bushing

The BP25 bronze self-lubricating bearing

The Metafram brand gained recognition for its self-lubricating bearings from the end of World War II. They have established themselves as a benchmark in the field of power transmission. In bronze alloy BP25, ferrous FP20 or SO16, this range of materials allows large operating ranges under load and speeds.

The performance of the BP25 bronze self-lubricating bushing

The standard bronze bushing offers operating ranges suitable for wide applications. BP25 self-lubricating bearings have a very good coefficient of friction, down to 0.01.

The Metafram bronze bushing is recommended for high speeds of up to 6 m/s thanks to the self-lubrication. The good corrosion resistance gives this ring very wide fields of application such as the marine atmosphere, nuclear power or contact with food products.

The operation of the self-lubricating bronze bushing

Metafram BP25 material is self-lubricating. Its impregnation forms an oil meniscus between the shaft and the bearing which gives it a long service life. This bronze bearing is maintenance free.

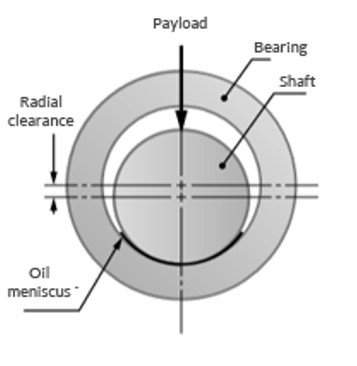

Shaft in contact with the self-lubricating bearing

Presence of an oil meniscus under the action of capillary forces at the point of contact.

This oil meniscus is very useful for lubrication at start-up.

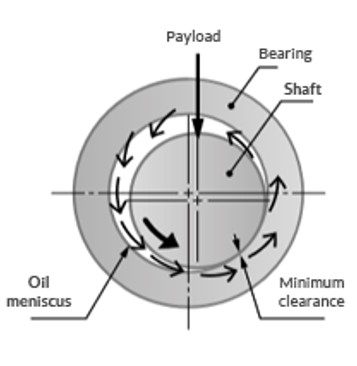

Oil is sucked from the self-lubricating bushing in the depression area at the top.

The oil is driven by the rotation of the shaft and forms an oil wedge that produces the pressure necessary to lift the shaft.

Some of the circulating oil is forced, under the action of pressure, into the pores of the self-lubricating bushing.

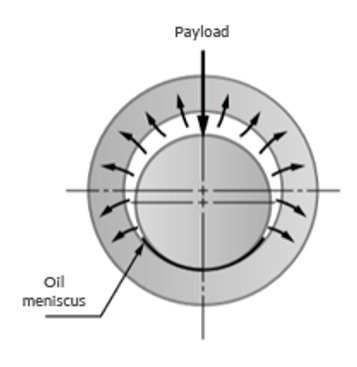

The oil is reabsorbed by the self-lubricating pad under the action of capillary forces.

The oil meniscus stays at the contact point ready for instant lubrication on new start-up.

The material variants of the BP25 bronze bushings

Other variations of the BP25 material exist. We have in our alloy range on request high speed materials up to 8 m/s or dry lubrication for specific applications. You can find this information in our brochure, or contact us to study your specifications.

Self-lubricating bronze ring available with flange, cylindrical or as a machinable blank

Other variants of the BP25 material exist. We have in our alloy range on request high speed materials up to 8 m / s or dry lubrication for specific applications. You can find this information in our brochure, or contact us to study your specifications.

This is the most classic standard bronze model used for guiding or rotating applications.

Bore diameter : Ø1 – Tolerance F7 (F8 for Ø1> 50 mm)

Outside diameter : Ø2 - Tolerance : s7 (s8 for Ø2> 50 mm)

Overall lenght : L > 10 Tolérance : 1 %

Overall lenght : L ≤ 10 Tolérance : 0,10 mm

The variation of the cylindrical ring with a flange

Bore diameter : Ø1 – Tolerance F8

Outside diameter : Ø2 - Tolerance S8

Overall lenght : L > 10 Tolérance : 1 %

Overall lenght : L ≤ 10 Tolérance : 0,10 mm

Nous proposons également des ébauches. En respectant les recommandations Metafram il est possible de les usiner.

Nous proposons une large gamme d’ébauches autolubrifiante pour répondre au besoin de pièces spéciales ou de petites séries.

Custom bronze ring

Regarding custom bronze bushings, we offer our customers a wide range of alloys and impregnation to meet their specifications. You can find this information on the self-lubricating bushing presentation page.

The machining of a self-lubricating bushing

BP25 self-lubricating bearings can be remanufactured for length modification, tolerance adjustment or blank machining. Certain precautions must be taken to maintain the self-lubricating aspect of the part. BP25-specific tools must be used as well as adequate re-impregnation.